100% Vertically Integrated

Our expertise lies in crafting advanced aroma and protection solutions.

We blend the artisanal knowledge of cooperage with cutting-edge parapharmaceutical technologies to ensure unparalleled quality and precision. Our involvement across beer, wine, spirits, and other industries enhances our market insight and fosters innovation, allowing us to consistently deliver solutions that anticipate and adapt to evolving industry trends.

Our Approach

Our approach centers on product quality and environmental responsibility, focusing on sustainable resource management, the impact of our production processes, and the effects our products have during their use. Every aspect of our operations is designed to minimize carbon emissions, from our use of decarbonized energy to our minimalist, recyclable packaging. This commitment to low-impact production doesn’t compromise our premium standards—rather, it strengthens them, demonstrating that excellence and sustainability can go hand in hand to meet the highest expectations of our clients and the environment.

Our Key Steps

Sourcing & Seasonning

As a supplier of oak for the cooperage industry, we carefully select our trees and mature the wood in open-air yards for 36 months. This natural aging process refines the aromas, ensuring optimal quality and complexity in the final product.

Thermal Processing

We design our own machines, inspired by the pastry industry, to perform precise heat treatments that reveal the ideal aromas for beer. This technology ensures consistently refined and repeatable flavor profiles, perfectly suited to brewing needs.

Low Temperature Extraction

We have thoroughly researched the molecules in oak that deliver aroma, structure, protection, and aging support. We’ve developed a complex extraction process that isolates only these essential molecules, using low-temperature extraction with osmosized water. This method ensures optimal purity and performance, enhancing the beer’s flavor and longevity.

Additionally, this process has a very low carbon footprint, making it an environmentally responsible solution.

Timing of Addition

After Fermentation

during the conditioning phase (Bright tank).

The quality of extraction depends on the temperature (the lower the temperature, the more limited and slow the extraction).

with Hops

Possibility of adding chips or extract with hops.

Gain in complexity.

Optimal Contact Time:

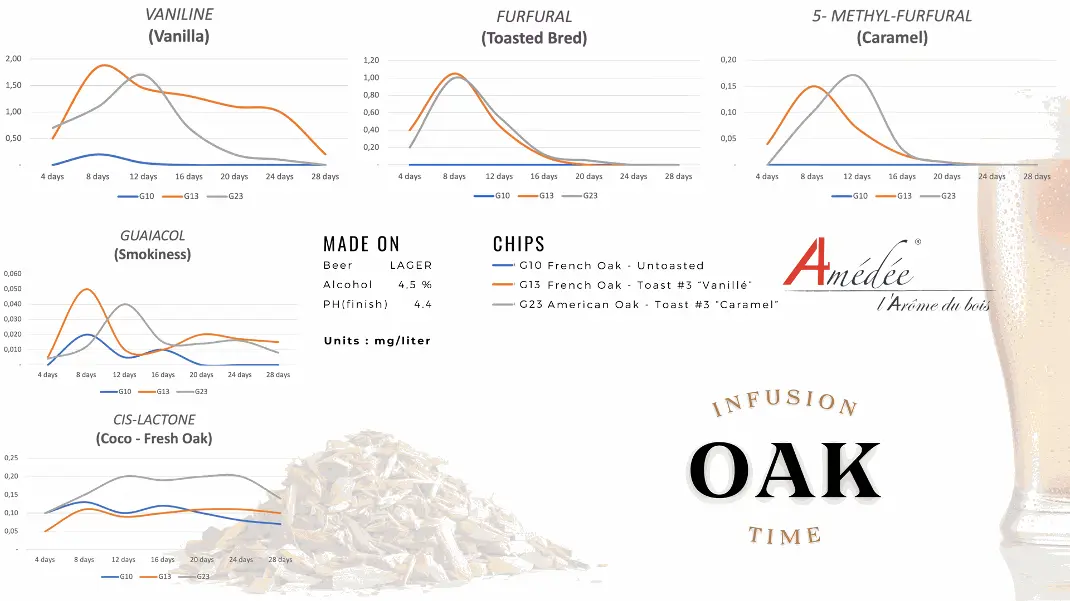

Chips

At 15-18°C: 10 days minimum - 12 days maximum.

At 7-10°C: 15 days minimum - 25 days maximum.

Extracts

10 Days

(and just so easy)

Staves (not industry standard but great results)

more qualitative (more integrated, complex, stable, but longer)

At 15-18°C: 22 days minimum - 30 days maximum.

At 7-10°C: 5 weeks minimum - 8 weeks maximum.

Timing & Impact

For Chips, beyond the maximum duration, the yield will be less marked.

The lower the temperature, the slower the extraction.

USING CHIPS : SANITATION REQUIRED

Sanitizing oak chips is essential in beer brewing to ensure purity and control over flavor. By eliminating any potential microorganisms naturally present in oak, we safeguard the beer’s taste profile, allowing only the desired woody notes to enhance the brew. This process preserves both the quality and safety of the beer, ensuring a refined and consistent drinking experience.

option #1 : Immerse wood in a neutral alcoholic solution of at least 10% for 24 hours.

option #2: Boil the wood in water for 15 minutes. Reuse this water in the brew.

Ready to Elevate Your Brewing Journey?

Contact us today to discover how our innovative and sustainable aroma solutions can transform your beers with natural, oak-derived flavors.

Your path to crafting exceptional brews begins here.